Soft Magnetic Alloys with High Permeability and High Saturation Magnetic Induction Iron-Nickel Alloys for Sealing to Glasses and Ceramic Alloy 52, Class 2, ASTM F 30, UNS N14052 acc. to AMS-I-23011A(Instead of MIL-I-23011C)

Quick view

Alloy 52, UNS N14052, ASTM F30, - Introduction and Application

Fairly high saturation magnetic induction and permeability Alloy 52 include magnetic reed switches and seals that need controlled linear expansion to approximately 977 °F (525 °C). Alloy 52 is a 50.50% nickel-iron alloy developed for glass-to-metal seals for some of the soft glasses and some ceramics. The alloy's rate of thermal expansion is virtually constant to a temperature of about 1050 °F (565 °C)., Nilo 52 is a Nickel-Iron alloy, belongs to the family of low expansion alloys as it has stable coefficient of thermal expansion up to 1050of. High strength and hardness at the cryogenic temperature limits. It is referred as controlled expansion alloy with low coefficient of thermal expansion in the low and high temperature limits up to 565oC. It is hard and ductile and attains low dispersion. It is used in radar & microwave cavity resonating devices, shadow masks, electric gun modules, glass to metal sealing etc. Cores oi various transiormers .relays.elecuomagnetic clutches and reactors in medium magnetic field.pole shoes .relay components oi earth leakage breakers.gas teliei valves.magnetic shielding.gyroscopes.automatic synchronous motors and minisize motors.etc.

AMS-I-23011A(Instead of MIL-I-23011C) specification has been declared "NONCURRENT" by the Aerospace Materials Division, SAE, as of August, 2007. It is recommended, therefore, that this specification not be specified for new designs. "NONCURRENT" refers to those specifications which have previously been widely used and which may be required for production or processing of existing designs in the future. The Aerospace Materials Division, however, does not recommend these specifications for future use in new designs.This specification covers a series of iron-nickel, iron-nickel-cobalt, and iron-nickel-chromium alloys used for sealing to glasses and ceramics in electronic applications.

Finishes shall be as follows:

Hot rolled or forged

Cold drawn or rolled

Centerless ground

Belt polished

Alloy 52, UNS N14052, ASTM F30, - Chemical composition WT %

| Grade | Chemical Composition WT % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Al | Co | Fe | |

| AMS-I-23011 Class 1, ASTM F 15, UNS 94610 | 29 | 17 | Bal | |||||||

| Allpy 52, UNS N14052, AMS-I-23011 Class 2, ASTM F 30 | Max 0.05 | Max 0.6 | Max 0.3 | Max 0.025 | Max 0.025 | Max 0.25 | 50.5 | Max 0.1 | * | Bal |

| AMS-I-23011 Class 3, ASTM F 30, UNS 94800 | 48 | Bal | ||||||||

| AMS-I-23011 Class 4, ASTM F 30, UNS 94600 | 46 | Bal | ||||||||

| AMS-I-23011 Class 5, ASTM F 30, UNS 94100 | 41 | Bal | ||||||||

| AMS-I-23011 Class 6, ASTM F 31, UNS 94760 | 5.5 | 41 | Bal | |||||||

| AMS-I-23011 Class 7, ASTM F 1684, UNS 93603 | 36 | Bal | ||||||||

* Cobalt is present as an incidental element and shall be reported separately.

Mechanical Property of Alloy 52, UNS N14052, ASTM F30,

- Tensile Strength: 80 ksi or 552 MPa

- Yield strength: 40 ksi or 276 MPa

- Elongation % in 2 inches: 35

+Annealed

- Tensile strength: 450 to 550 N/mm2 or 65 to 80 ksi

- Service temperature: 450 oC or 840 oF

+Hard Drawn

- Tensile strength: 700 to 900 N/mm2 or 102 to 131 ksi

- Service temperature: 450 oC or 840 oF

Physical Property of Alloy 52, UNS N14052, ASTM F30,

- Thermal Conductivity:

- Density: 0.3 lb/cu-inch

- Specific gravity: 8.3

- Electrical Resistivity: ohm-cir-mil/ft, microhm-cm: At 68 °F (20 °C): 258 (43)

- Curie temp: 986 oF or 530 oC

- Melting point: 2600 oF or 1427 oC

- Electrical resistivity: 44 micro-ohm-cm 258 ohm-cir mil/ft

- Thermal conductivity: 0.14 W/cm.oC or 97 BTU-inch/sq. ft-hr, BTU-in/hr-ft2-°F (W/m•K): 68 - 212 °F (20 - 100 °C): 97 (140)

- Specific heat: 0.12 Cal/g-oC or 0.12 BTU/lbm-oF

- Thermal expansion: 5.5 ppm/oF at 75oF to 842oF, 9.9 ppm/oC at 25oC to 450 oF

- Mean Coefficient of Thermal Expansion: µin/in-°F (µm/m-°C): 77 - 842 °F (25 - 450 °C): 5.4 (9.8)

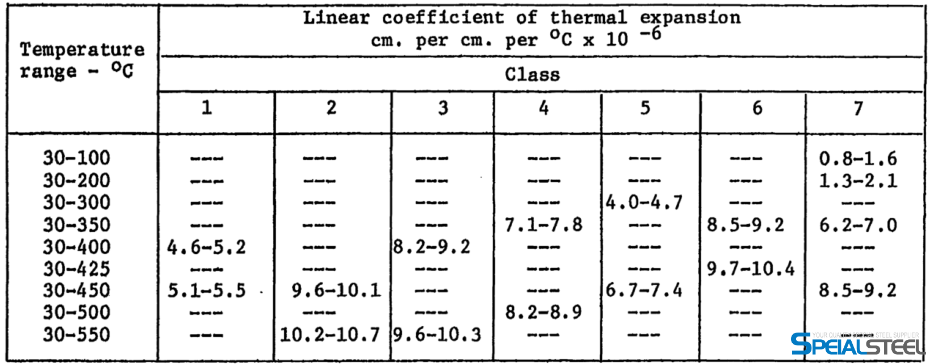

Linear Coefficient of thermal expansion

Heat Treatment of Alloy 52, UNS N14052, ASTM F30,

Condition and temper: Condition and temper shall be as follows (see Tables IV and V):

Annealed

- 1 /4 Hard (one quarter hard temper)

- 1 /2 Hard (one half hard temper)

- Hard (full hard temper)

Machining of Alloy 52, UNS N14052, ASTM F30,

Cold processing is not suitable for Allpy 52(UNS N14052) because it disturbs the coefficient of thermal

expansion. Allpy 52(UNS N14052) is annealed at temperature of 850oC to 1000oC.

The properties of processed of Allpy 52(UNS N14052) are shown as following:

| Condition | Tensile Strength | Approx. service temperature | ||

| Annealed | 450 – 550 N/mm2 | 65 - 80 ksi | up to 450 oC | up to 840 oF |

| Hard Drawn | 700 - 900 N/mm2 | 102 - 131 ksi | up to 450 oC | up to 840 oF |

Equivalent grades of Alloy 52, UNS N14052, ASTM F30,

Alloy 52, UNS N14052, ASTM F30In the steel grades above we can supply:

- Alloy 52, UNS N14052, ASTM F30, Steel bar

- Alloy 52, UNS N14052, ASTM F30, Steel plate and sheet

- Alloy 52, UNS N14052, ASTM F30, Open die and closed die forgings and forged steel

- Alloy 52, UNS N14052, ASTM F30, Hot extrusion and cold-rolled welded seamless tubes pipe

- Alloy 52, UNS N14052, ASTM F30, Hot-rolled and Cold-rolled strip steel

- Alloy 52, UNS N14052, ASTM F30, Steel wire

- Alloy 52, UNS N14052, ASTM F30, Special shaped

Steel grade

Category

- Stainless Steel and Corrosion Resistant Steel

- Nickel and High Temperature Alloys

- Maraging Martensitic Age Hardened Steel

- Tool steel

- Heat-Resistant Steel, Valve Steel, Creep-Resistant Alloy

- High-alloy and low-alloy ultra-high-strength steel

- Boiler steel

- Precision alloys

- Non-magnetic steel

- Alloy Structural Steels

Special steel